Metacoat®

In-Chamber Coating and Metallizing

- Lower Capital and Operating Costs

- Excellent, predictable barrier properties

- Possibilities for new laminated and unlaminated structures

- Environmentally reduces: Materials, energy use and Carbon footprint

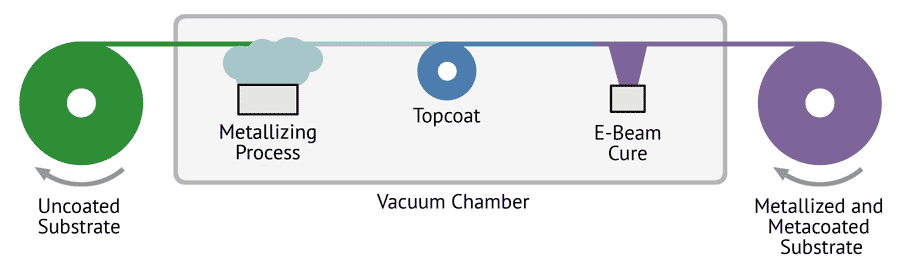

Metacoat® is the first technology in the world that enables flexo printing of EB curable coatings at production speeds in the high vacuum environment of a metallizing chamber. This technology, covered by several patents, allows for streamlined operations, with the ability to both metallize and coat in a single pass. Also, by protecting the metal layer immediately after the deposition zone, significant barrier improvements can be achieved on a wide variety of substrates.

Inline Coating and Metallizing Process

Lower Capital and Operating Costs

The Economics of One Step vs. Two Step Coating and Metallizing

2 Step Process

Capital Investment:

Two units and two production areas

= Higher fixed costs

Operating Costs:

Requires two sets of operators

Yield losses > 10%

= Higher operating costs

1 Step Metacoat® Process

Capital Investment:

One unit and one production area

= Lower fixed costs

Operating Costs:

Requires one set of operators

Yield losses ~ 5%,

= Lower operating costs

Improved Barrier Properties

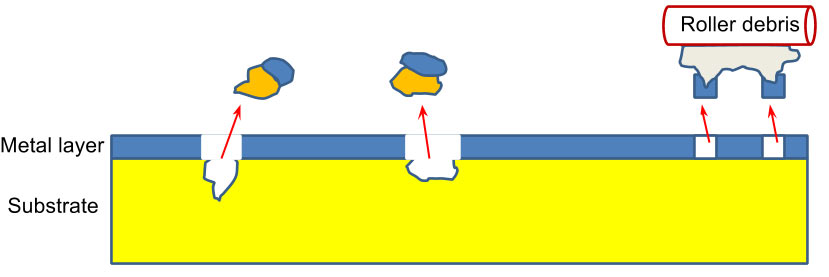

The Metacoat® process seals and protects the metallized layer inside the chamber, significantly improving and stabilizing barrier properties.

The causes of defects:

- Scratches

- Impurities flaking off

The in-chamber coating protects the metal layer and impurities are trapped.

When comparing coated and uncoated metallized samples under a strong backlight: The uncoated samples have higher levels of pinholes than the coated ones.

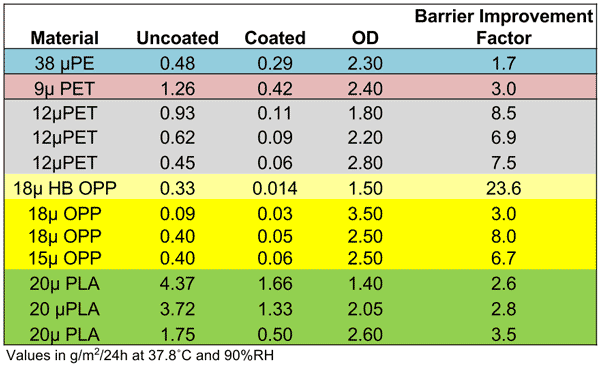

WVTR Values

OTR Values

WVTR vs. Optical Density

Significantly improve barrier properties of a film without having to work at optical densities greater than 2.0 – 2.2

Barrier Properties of Several Metallized and Coated Films

Design a product knowing what your barrier properties will be.

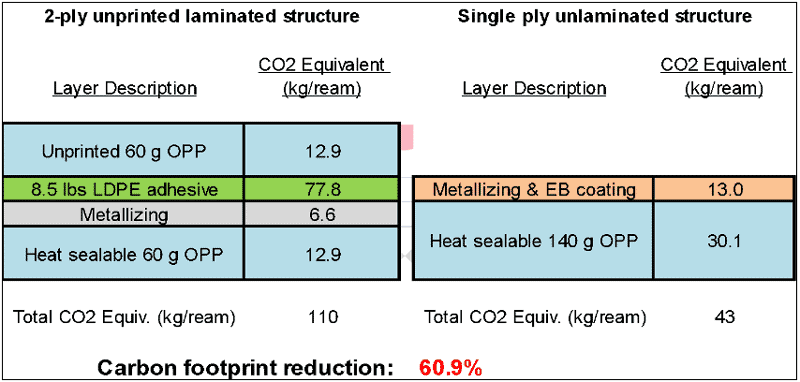

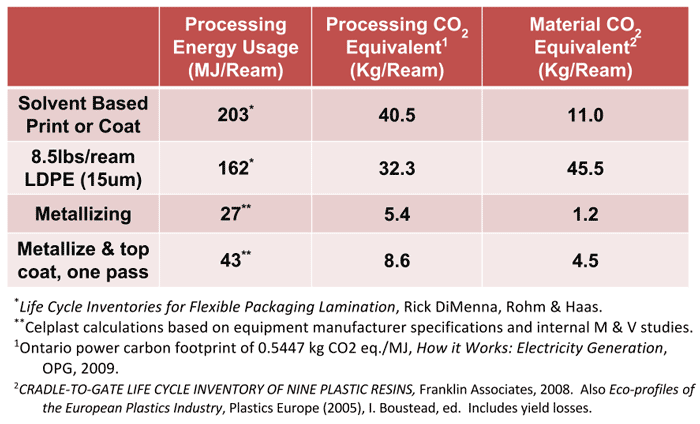

Reduced Environmental Impact

Reduction of Materials, energy use and Carbon footprint

Converting Operations

Layer Elimination

Potential layer elimination for 2 different structures:

- Dry powder pouch : Aluminum foil

- Bag-in-box pouch: Metallized OPP

It also allows us to look at eliminating additional plies of material, that are there primarily to protect the metallized layer

Dry Powder or Stick Pack

%

Carbon Footprint Reduction vs. Solvent Based

Click to Enlarge

%

Carbon Footprint Reduction vs. Solvent-less

Click to Enlarge

%

Material Reduction vs. Solvent-less

Click to Enlarge

Bag-in-box Snack Food

%

Carbon Footprint Reduction

Click to Enlarge

%

Material Reduction

Click to Enlarge

DataSheets

Metacoat Developmental Datasheets

Metallized & Top-coated Polyester Film. A bi-axially oriented polyester film exhibiting excellent heat reflection properties, a moisture protected metal layer, and bright foil appearance. Consistently good handling properties, heat stability, slip, and high tensile strength for easy lamination. Superior WVTR, OTR, and light barrier properties.

Whitepapers

Improve Barrier Properties and Significantly Reduce Your Carbon Footprint with In-Line Metallizing and Top-Coating

The traditional method of preparing a top-coated metallized film using roll-to- roll processes is to carry out two separate, independent steps. This two-step process creates certain inherent disadvantages, such as high operating and capital costs

Barrier Packaging in the Real World

Two trends are driving much of the innovation in laminations using metallized film today.

Properties of EB Top-Coated Metallized Films Prepared in Vacuum

This two-step process creates certain inherent disadvantages, which we attempted toovercome by retrofitting a traditional single zone free-span metallizing chamber with an in-line top-coating process directly after the metallizing area.

Metacoat™ technology meets FDA food contact requirements for use with all food types under Condition of Use E. Metacoat also complies with relevant requirements of the Swiss Chemicals Ordinance SR 813.11(ChemO) and European Regulation No. 10/2011 for food contact.

Streamlined operations,

Improved barrier properties,

and environmental advantages.

In-chamber coating is where the industry is headed.

Metallized Surface Technologies, LLC

MST an Intellectual Property Company which markets and licenses surface treatments on flexible substrates under vacuum. The first such treatment is Metacoat®.

Contact us for technical details, Metacoat® licencing and machinery information

Metacoat® captured the 2010 AIMCAL Technology of the Year Award, shown here with Chuck Larsen and Dante Ferrari of MST

Dante Ferrari

Technical & Sales, Partner

E-mail: dante@mstmetacoat.com

Phone: +1 (416) 644 3507

Chuck Larsen

Partner

E-mail: chuck@mstmetacoat.com

Stay Informed

We will let you know of any developments.